Diy Sheet Metal Brake Plans

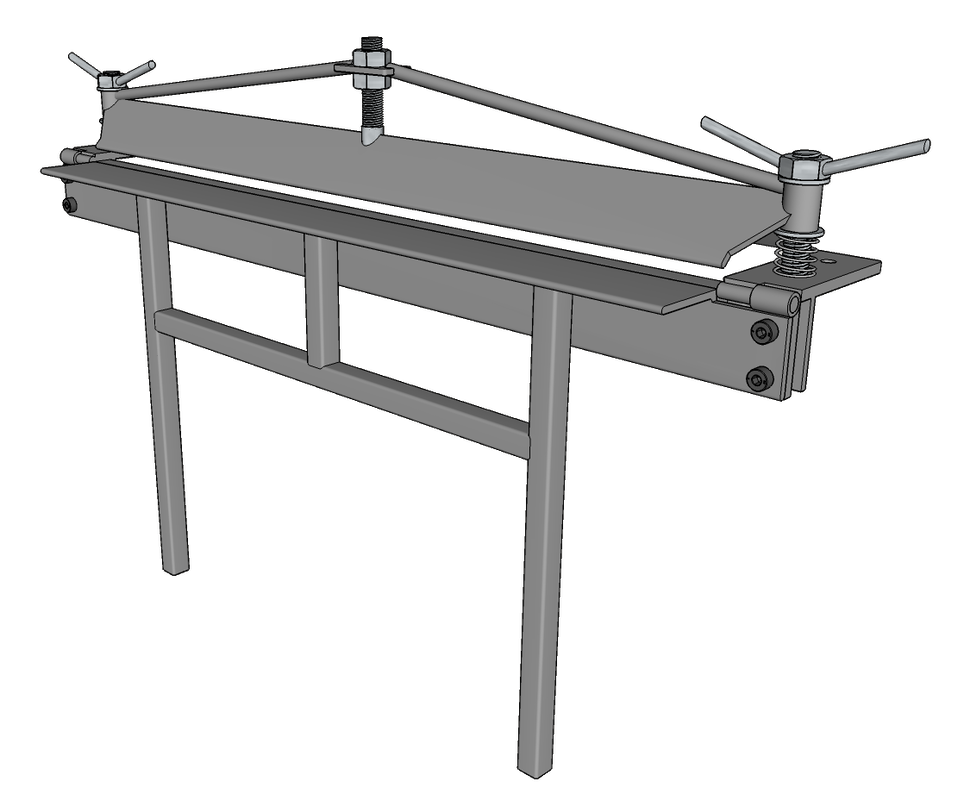

Diy Sheet Metal Brake Plans - Link to free plans below! I started looking into it and found lots of diy versions online. But you can use your welding table, or bench, a channel iron, or a rectangular tube. Select materials that will be strong enough for your needs. Calculate the desirable full width of sheet metal. 36 glory, cantilever locking mechanism, adjustable fingers, weighs as much as i do! 1⁄4 inch (0.6 cm) steel plate with bracing will enable. Web 767k views 3 years ago. How to build a simple sheetmetal brake. Cut the angle iron and steel plate in sizes listed above, making sure edges.

Select materials that will be strong enough for your needs. Web while on a google hangout with my patreon supporters, my friend evan mentioned making a sheet metal brake. 1⁄4 inch (0.6 cm) steel plate with bracing will enable. The sheet metal brake i always wanted: But you can use your welding table, or bench, a channel iron, or a rectangular tube. 36 glory, cantilever locking mechanism, adjustable fingers, weighs as much as i do! How to build a simple sheetmetal brake. Web diy sheet metal bender brake step 1: Cut the angle iron and steel plate in sizes listed above, making sure edges. I started looking into it and found lots of diy versions online.

1⁄4 inch (0.6 cm) steel plate with bracing will enable. Select materials that will be strong enough for your needs. Web while on a google hangout with my patreon supporters, my friend evan mentioned making a sheet metal brake. Calculate the desirable full width of sheet metal. The sheet metal brake i always wanted: Link to free plans below! Web diy sheet metal bender brake step 1: I started looking into it and found lots of diy versions online. Cut the angle iron and steel plate in sizes listed above, making sure edges. 36 glory, cantilever locking mechanism, adjustable fingers, weighs as much as i do!

DIY Sheet Metal Brake Plans (Simpe To Build Design)

1⁄4 inch (0.6 cm) steel plate with bracing will enable. 36 glory, cantilever locking mechanism, adjustable fingers, weighs as much as i do! Web diy sheet metal bender brake step 1: Cut the angle iron and steel plate in sizes listed above, making sure edges. How to build a simple sheetmetal brake.

Pin on Herrería Blacksmith

Web 767k views 3 years ago. Web diy sheet metal bender brake step 1: How to build a simple sheetmetal brake. Calculate the desirable full width of sheet metal. But you can use your welding table, or bench, a channel iron, or a rectangular tube.

See How You Can Make Your Own DIY Sheet Metal Brake At

But you can use your welding table, or bench, a channel iron, or a rectangular tube. Select materials that will be strong enough for your needs. Link to free plans below! How to build a simple sheetmetal brake. Web diy sheet metal bender brake step 1:

Sheet metal bending brake Artofit

The sheet metal brake i always wanted: Web 767k views 3 years ago. Select materials that will be strong enough for your needs. Cut the angle iron and steel plate in sizes listed above, making sure edges. 36 glory, cantilever locking mechanism, adjustable fingers, weighs as much as i do!

Sheet Metal Brake Plans Renewable Systems Technology

Select materials that will be strong enough for your needs. I started looking into it and found lots of diy versions online. 1⁄4 inch (0.6 cm) steel plate with bracing will enable. Link to free plans below! Web diy sheet metal bender brake step 1:

Pin on Shop ideas, Tools and hacks

Cut the angle iron and steel plate in sizes listed above, making sure edges. 1⁄4 inch (0.6 cm) steel plate with bracing will enable. We’ve poked at bending sheetmetal in a previous installment of wrenchin’ wednesday, but today we’re going to talk about how to. Calculate the desirable full width of sheet metal. Web 767k views 3 years ago.

Sheetmetal Folder/Bender Brake Plans Plans for U

Select materials that will be strong enough for your needs. But you can use your welding table, or bench, a channel iron, or a rectangular tube. Link to free plans below! We’ve poked at bending sheetmetal in a previous installment of wrenchin’ wednesday, but today we’re going to talk about how to. I started looking into it and found lots.

How to make a metal brake (for folding sheet metal) LaptrinhX

Calculate the desirable full width of sheet metal. We’ve poked at bending sheetmetal in a previous installment of wrenchin’ wednesday, but today we’re going to talk about how to. But you can use your welding table, or bench, a channel iron, or a rectangular tube. Web diy sheet metal bender brake step 1: Web while on a google hangout with.

Sheet Metal Bending Brake Woodworking Project Woodsmith Plans

But you can use your welding table, or bench, a channel iron, or a rectangular tube. Calculate the desirable full width of sheet metal. How to build a simple sheetmetal brake. The sheet metal brake i always wanted: Web while on a google hangout with my patreon supporters, my friend evan mentioned making a sheet metal brake.

Sheet Metal Brake Plans • WoodArchivist

I started looking into it and found lots of diy versions online. Cut the angle iron and steel plate in sizes listed above, making sure edges. Web diy sheet metal bender brake step 1: We’ve poked at bending sheetmetal in a previous installment of wrenchin’ wednesday, but today we’re going to talk about how to. Select materials that will be.

Web Diy Sheet Metal Bender Brake Step 1:

Web 767k views 3 years ago. Web while on a google hangout with my patreon supporters, my friend evan mentioned making a sheet metal brake. How to build a simple sheetmetal brake. I started looking into it and found lots of diy versions online.

Cut The Angle Iron And Steel Plate In Sizes Listed Above, Making Sure Edges.

Select materials that will be strong enough for your needs. The sheet metal brake i always wanted: 1⁄4 inch (0.6 cm) steel plate with bracing will enable. We’ve poked at bending sheetmetal in a previous installment of wrenchin’ wednesday, but today we’re going to talk about how to.

Link To Free Plans Below!

36 glory, cantilever locking mechanism, adjustable fingers, weighs as much as i do! Calculate the desirable full width of sheet metal. But you can use your welding table, or bench, a channel iron, or a rectangular tube.