Sheet Roll Form

Sheet Roll Form - The system will end your session after 60 minutes of inactivity and no information will be saved. Samuel roll form group offers an extensive line of cold rolled and hot rolled sheet piling including l series, s series, z series, ez series, xz series, pz series, pzc series and jz series. Once the required shape has been achieved, the metal can be cleaned, anodized, detailed, and cut into desired lengths. Web roll forming is the process in which sheet metal is sent through a series of rollers which flatten, bend, and shape the sheet metal into the desired profile. Web the form must be electronically completed, signed, and submitted in a single session. The rollers are mounted in sets on a consecutive stand with each roller completing one small step of the process. Computer extract of social security card application. Web at samuel roll form group, we have domestic sheet pile corner connectors priced to sell and ready to ship across the us. Social security uses the work activity report form to learn more about the work activity of a disability applicant or beneficiary. Web the forming is completed by tool steel rolls as they roll over the work metal.

Read more get a quote. Social security uses the work activity report form to learn more about the work activity of a disability applicant or beneficiary. Web the forming is completed by tool steel rolls as they roll over the work metal. Web the form must be electronically completed, signed, and submitted in a single session. Web roll forming services for channels, frames, and shapes. Thickness, 2 to 19 in. If you are applying for disability benefits, the information you provide will help us decide if you can receive benefits. Request for deceased individual’s social security record *use this form if you need 1. Computer extract of social security card application. Once the required shape has been achieved, the metal can be cleaned, anodized, detailed, and cut into desired lengths.

Works with steel, stainless steel, cold rolled steel, galvanized steel, high strength steel, and hot rolled steel. Alternatively, you can send (1) the person's name, (2) the person's social security number (if known), and (3) either. Web sheet metal roll forming is a type of pressing in which the sheet metal is continuously rolled to form the desired metal section and is one of the most practical ways of forming large quantities of metal that are widely used today.it is a roll forming process in which multiple pairs of forming rollers deform the metal plate in sequence and feed. Web the forming is completed by tool steel rolls as they roll over the work metal. Ultimately, as the progression of the desired bend or fold increases, more wheels or dies are required to make it happen. Roll forming is a metalworking process that uses contoured tools to bend flat sheets from coiled steel into a finished, uniform profile. Each roll changes the shape of the sheet metal successively as it advances on the line. Request for deceased individual’s social security record *use this form if you need 1. The process is performed on a roll forming line in which the sheet metal stock is fed through a series of roll stations. Web as a continuous process.

Roll Call/Attendance Sheets Procare Solutions

Web sheet piling is often used to create a safe work environment during the construction or repair of levies that have been damaged by hurricanes, floods, or erosion. Once the required shape has been achieved, the metal can be cleaned, anodized, detailed, and cut into desired lengths. Web in the roll forming process, a strip of metal is fed through.

Roll Call Template Business Mentor

The strip passes through sets of rolls mounted on consecutive stands, each set performing only an incremental part of the bend, until the desired. Virtually any material that can be formed by sheet forming techniques can be roll formed. The sum of these small changes in form is a complex profile. Social security uses the work activity report form to.

Roll Template Classles Democracy

Social security uses the work activity report form to learn more about the work activity of a disability applicant or beneficiary. Each roll changes the shape of the sheet metal successively as it advances on the line. Samuel roll form group offers an extensive line of cold rolled and hot rolled sheet piling including l series, s series, z series,.

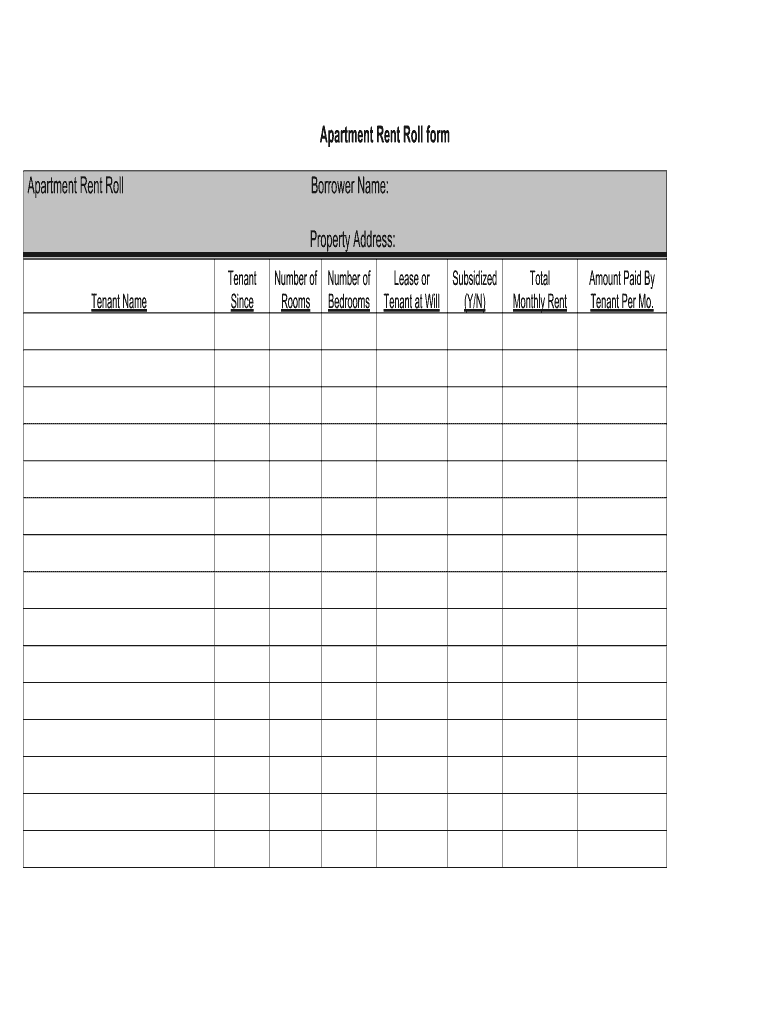

11+ Rent Roll Template Editable Free Download [Word, PDF]

Web sheet piling is often used to create a safe work environment during the construction or repair of levies that have been damaged by hurricanes, floods, or erosion. Spindle dia., 20 to 8 ga. The system will end your session after 60 minutes of inactivity and no information will be saved. Roll forming is a metalworking process that uses contoured.

FREE 14+ Rent Roll Form Templates in PDF MS Word

Works with steel, stainless steel, cold rolled steel, galvanized steel, high strength steel, and hot rolled steel. Web roll forming, sometimes spelled rollforming, is a metal forming process in which sheet metal is progressively shaped through a series of bending operations. Samuel roll form group offers a variety of hot and cold rolled options to keep any levy construction site.

Roll Form Labels God Labels and Packaging

The process is performed between successive pairs of rolls that change the shape until the desired section is completed. Samuel roll form group offers a variety of hot and cold rolled options to keep any levy construction site safe. Web roll forming is a process that uses a set of precisely placed rollers to perform incremental bending to a continuously.

Roll Sheet Template SampleTemplatess SampleTemplatess

Read more get a quote. Spindle dia., 20 to 8 ga. Web the form must be electronically completed, signed, and submitted in a single session. Virtually any material that can be formed by sheet forming techniques can be roll formed. Web what is sheet metal roll forming?

Rent Roll Form Templates for MS Word Word & Excel Templates

We also offer piling accessories including walers, pile caps, tie rods, corners, fasteners and structurals, just to name a few. Web roll forming is a continuous metal forming process taking sheet, strip, or coil stock and bending or forming it to a continuous cross section. Samuel roll form group offers an extensive line of cold rolled and hot rolled sheet.

15+ Free Rent Roll Templates Word Excel Fomats

Web roll forming is a process that uses a set of precisely placed rollers to perform incremental bending to a continuously fed strip of metal. Works with steel, stainless steel, cold rolled steel, galvanized steel, high strength steel, and hot rolled steel. The sum of these small changes in form is a complex profile. Web roll forming services for channels,.

Sample Rent Roll Report Classles Democracy

Length, 0.06 to 0.18 in. Width, 24 to 280 in. Request for deceased individual’s social security record *use this form if you need 1. Social security uses the work activity report form to learn more about the work activity of a disability applicant or beneficiary. This material is also applied in sectors such as aerospace, appliance, automotive, construction, energy, hvac,.

Works With Steel, Stainless Steel, Cold Rolled Steel, Galvanized Steel, High Strength Steel, And Hot Rolled Steel.

Web roll forming is a continuous process which converts sheet metal into an engineered shape using consecutive sets of mated rolls, each of which makes only incremental changes in the form. Web at samuel roll form group, we have domestic sheet pile corner connectors priced to sell and ready to ship across the us. The strip passes through sets of rolls mounted on consecutive stands, each set performing only an incremental part of the bend, until the desired. Web roll forming services for channels, frames, and shapes.

Web In The Roll Forming Process, A Strip Of Metal Is Fed Through A Series Of Mated Roll Dies That Are Installed Onto The Shafts Of A Mill’s Forming Stands.

Read more get a quote. Ultimately, as the progression of the desired bend or fold increases, more wheels or dies are required to make it happen. We also offer piling accessories including walers, pile caps, tie rods, corners, fasteners and structurals, just to name a few. Heavy construction we are a major north american producer and supplier of hot rolled and cold formed steel sheet piling sections.

If You Are Applying For Disability Benefits, The Information You Provide Will Help Us Decide If You Can Receive Benefits.

An email reminder will be sent every three (3) days for fifteen (15) days or until the form has been submitted. Web what is sheet metal roll forming? Web roll forming, sometimes spelled rollforming, is a metal forming process in which sheet metal is progressively shaped through a series of bending operations. Thickness, 2 to 4 in.

Spindle Dia., 20 To 8 Ga.

Width, 24 to 280 in. The sum of these small changes in form is a complex profile. Web sheet metal roll forming is a type of pressing in which the sheet metal is continuously rolled to form the desired metal section and is one of the most practical ways of forming large quantities of metal that are widely used today.it is a roll forming process in which multiple pairs of forming rollers deform the metal plate in sequence and feed. Samuel roll form group offers a variety of hot and cold rolled options to keep any levy construction site safe.

![11+ Rent Roll Template Editable Free Download [Word, PDF]](https://www.opensourcetext.org/wp-content/uploads/2020/08/rrt-10.jpg)