Slip Form Construction

Slip Form Construction - How much lead time is required to start a slipform project? It involves the use of a moving formwork system that gradually rises as the concrete is poured, allowing for continuous construction without the need for joints. Features of slipform construction ; Define slip formwork pouring concrete requires a mold known as formwork, which is temporary. See reviews, photos, directions, phone numbers and more for the best road building contractors in kansas city, mo. The process stops once casting is complete. Slipform construction involves the formwork for the walls being raised in a continuous process as the wall concrete is poured. Construction of regular core high rise structures; Web slip form concrete is a method of construction in which concrete is poured into the top of a continuously moving shallow form. Web summary • slip form construction is a construction method in which concrete is poured into a continuously moving form.

Slip forming is used for tall structures (such as bridges, towers, buildings, and dams), as well as horizontal structures, such as roadways. Slip forming is used for tall structures (such as bridges, towers, buildings, and dams), as well as horizontal structures, such as roadways. Web slip form definition, a form into which concrete is poured that can be slowly moved and reused in construction, as of a pavement or a building. Ad complete, esign, and share construction forms in one place. Web slipform is a construction method for reinforced concrete walls, generally lift and stair core walls, and is often economical for buildings more than ten storeys in height. As the concrete is poured, the formwork is lifted vertically at a speed that allows the concrete to harden before it is free from the formwork at the bottom. Web slip forming, continuous poured, continuously formed, or slipform construction is a construction method in which concrete is poured into a continuously moving form. You pour concrete at the top of a moving formwork, and once you’ve poured the concrete, the formwork will be raised vertically. Web preparation & planning q (1): Web roofing repairs & remodeling services.

Slip formwork is an advanced method for building large towers or bridges. Web road construction in kansas city on yp.com. That's where we come in. Construction of regular core high rise structures; Web slip forming, continuous poured, continuously formed, or slipform construction is a construction method in which concrete is poured into a continuously moving form. Royal t construction is a preferred roofing contractor specializing in asphalt shingles, metal. Draft, manage, sign and send construction documents online. Shipping to the us takes about 4 weeks to the east coast and 6 weeks to the west coast. As the concrete is poured, the formwork is raised vertically at a speed that allows the concrete to harden before it is free from the formwork at the bottom. This construction technique utilizes a mechanized moving platform system enabling continuous placement of concrete.

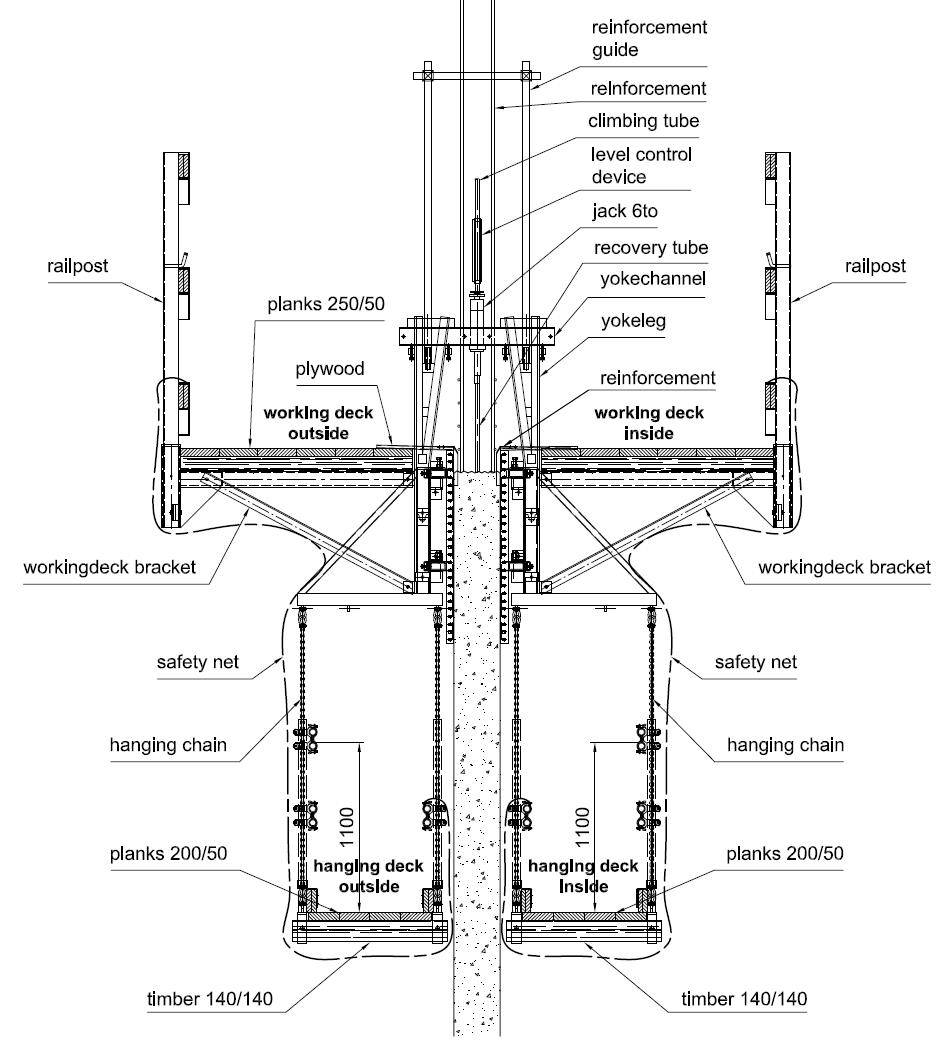

Slipform Construction Technique Uses, Components and Features

Web august 17, 2021. Slip form construction is pretty straightforward. The walls have the beauty and strength of stone with the reinforcement of concrete and. Web slip forming, continuous poured, continuously formed, or slipform construction is a construction method in which concrete is poured into a continuously moving form. As a rough guide, assume 6 to 10 weeks for design.

What Is Slip Form Slip Form Construction Slip Form Technique Slip

Web road construction in kansas city on yp.com. Shipping to the us takes about 4 weeks to the east coast and 6 weeks to the west coast. Web summary • slip form construction is a construction method in which concrete is poured into a continuously moving form. Disadvantages of slipform construction technique Slip form construction is pretty straightforward.

Slipform construction of reinforced concrete core of BRB A building

This construction technique utilizes a mechanized moving platform system enabling continuous placement of concrete. The process stops once casting is complete. Slipform construction involves the formwork for the walls being raised in a continuous process as the wall concrete is poured. 2500 west laurel street independence, ks 67301 ph: Advantages of slipform construction technique;

Slipform The Goto Method for Large Concrete Construction Dowsing Group

Draft, manage, sign and send construction documents online. That's where we come in. Web summary • slip form construction is a construction method in which concrete is poured into a continuously moving form. The process stops once casting is complete. Slip formwork is an advanced method for building large towers or bridges.

Drawings Concrete Slipform Construction

As the concrete is poured, the formwork is lifted vertically at a speed that allows the concrete to harden before it is free from the formwork at the bottom. Roofing is one of the last things on your mind, at least until there is a problem. As a rough guide, assume 6 to 10 weeks for design and preparation of.

Bitschnau Slipform Animation Gleitschalung, Slipforming YouTube

Slip form construction is pretty straightforward. That depends somewhat on the complexity of the project. The walls have the beauty and strength of stone with the reinforcement of concrete and. Slip formwork is an advanced method for building large towers or bridges. Web slipforming combines stone masonry and concrete work to form a wall that shares the attributes of both.

Slipform Technique A Method of Construction

Slip formwork is an advanced method for building large towers or bridges. This allows the concrete to harden quickly before it is free from the formwork at the bottom. Slip forming is used for tall structures (such as bridges, towers, buildings, and dams), as well as horizontal structures, such as roadways. Slip form construction is pretty straightforward. As the concrete.

Engineers HeadQuarter Useful Data for Site Execution (Construction

Web slip form is a construction technique used to continuously pour and mold concrete structures, such as walls, columns, or towers. Shipping to the us takes about 4 weeks to the east coast and 6 weeks to the west coast. Web slip form construction involves pouring concrete into the top of a continuously moving formwork. You pour concrete at the.

What is Slipform Construction? Patrick Parsons

This allows the concrete to harden quickly before it is free from the formwork at the bottom. That depends somewhat on the complexity of the project. This construction technique utilizes a mechanized moving platform system enabling continuous placement of concrete. Slipform construction involves the formwork for the walls being raised in a continuous process as the wall concrete is poured..

Slip Form Slip Form Construction Slipform Concrete Construction

The process stops once casting is complete. Roofing is one of the last things on your mind, at least until there is a problem. Web slip form definition, a form into which concrete is poured that can be slowly moved and reused in construction, as of a pavement or a building. Construction of regular core high rise structures; Get started.

Web Slip Forming, Continuous Poured, Continuously Formed, Or Slipform Construction Is A Construction Method In Which Concrete Is Poured Into A Continuously Moving Form.

This construction technique utilizes a mechanized moving platform system enabling continuous placement of concrete. Web slip form concrete is a method of construction in which concrete is poured into the top of a continuously moving shallow form. Shipping to the us takes about 4 weeks to the east coast and 6 weeks to the west coast. Disadvantages of slipform construction technique

Roofing Is One Of The Last Things On Your Mind, At Least Until There Is A Problem.

Draft, manage, sign and send construction documents online. The process stops once casting is complete. Slip form construction is pretty straightforward. This allows the concrete to harden quickly before it is free from the formwork at the bottom.

Web Roofing Repairs & Remodeling Services.

Ad complete, esign, and share construction forms in one place. That's where we come in. Slipform is identified as such because the. It involves the use of a moving formwork system that gradually rises as the concrete is poured, allowing for continuous construction without the need for joints.

Web Slip Formwork Is A Method Of Construction In Which Concrete Is Poured On Top Of A Continuously Moving Formwork.

Web slip forming, continuous poured, continuously formed, or slip form construction is a construction method in which concrete is poured into a continuously moving form. How much lead time is required to start a slipform project? As the concrete is poured, the formwork is raised vertically at a speed which allows the concrete to harden before it is. 2500 west laurel street independence, ks 67301 ph: